Category

Food Grade Sealing Rubber Gasket PTFE Silicone Seal Rubber Gasket

POLYTETRAFLUOROETHYLENE (PTFE) GASKETING PRODUCTSGasket & O-Ring ProductsPolytetrafluoroethylene (PTFE) is a synthetic f

Basic Info

| Model NO. | Y4153 |

| Production Capacity | 50000pieces etc. |

Product Description

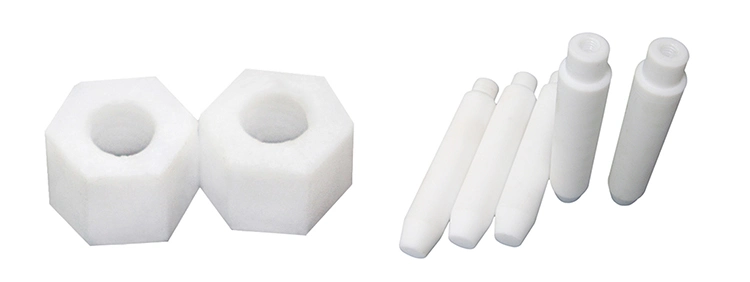

POLYTETRAFLUOROETHYLENE (PTFE) GASKETING PRODUCTSGasket & O-Ring ProductsPolytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene that has numerous applications. PTFE can be modified for use as a gasketing material with strong chemical resistance properties. It can also be machined or molded into almost any shape.PTFE Seals - Key Characteristics* Low coefficient of friction -the second lowest of any solid material. PTFE is suitable for most moving parts allowing them to glide over surfaces smoothly and with less effort. Suitable for bearings, gears and most sliding parts.* Excellent dielectric properties - one of the best thermally established and non-conducting plastic materials making it suitable for electrical insulators in circuit boards.* Good chemical resistance - PTFE is chemically inert and non-toxic and is used in chemical laboratories for containers, and stirrers where in contact with strong acids. It is solvent resistant up to 300°C.PTFE ENCAPSULATED O-RINGSPTFE is a superior O-Ring material not affected by most chemicals. It can be used at temperatures up to 500°F (260°C). It has the lowest coefficient of friction of any solid material. Lubrication is less critical and can sometimes be omitted.Elastomers such as silicone or Viton® can be coated in a PTFE sheath for added chemical resistance while maintaining maximum flexibility. These rings are often used in food & pharmaceutical, chemical, and petrochemical industries where strong chemical resistance and hygiene are required.

1.Plastic parts and materials (PTFE)PTFE(Poly Tetra Fluoro Etylene) has excellent heat resistance (about -250 to 260ºC), chemical resistance, abrasion resistance, and outstanding chemical resistance.It also has water-repellent, non-adhesive properties, much better slidability than other plastics. The surface feels very smooth.We can process the JIS-certified PTFE material into various shape such as plate, round bar, pipe. also welding and permeabilizing treatment.Please send us drawings, pictures, or your preference conditions.We will respond quickly and give you the best answer. All the product pictures on our website just show our machining capability and ranges. We offer machining service according to customer's drawings or samples.

| Product Name | CNC precision machined plastic PTFE parts | ||

| Material | stainless steel/aluminum/brass/copper/steel | ||

| Surface finish | polishing/anodize/powder coating/zinc platedrome plated | ||

| Tolerance | ISO2768-M | ||

| File format | solidworks, pro/engineering, auto cad, pdf, jpg | ||

| Inspection | IQC/IPQC/FQC/QA | ||

| Machining Equipment | CNC millinging machine, tuning machine, grinding machine | ||

| Used | auto, motorcycle, industry, agriculture, furniture, elevator | ||

Seven characteristics:1. Weather resistance, the best aging life among plastics.2. Corrosion resistance, strong acid and alkali resistance, water and various organic solvents.3. High lubrication, with the smallest coefficient of friction in plastics (0.04)4. High temperature resistance, long-term use temperature is 200~260C.5. Low temperature resistance, even if the temperature drops to -1960C, it can maintain 5% elongation.6. It does not adhere, which is the smallest surface tension among solid materials, and does not adhere to any substance.7. Excellent electrical performance. It is an ideal C-level insulating material. A thick layer of newspaper can blockthe high voltage of 1500V.

ApplicationWe have a professional engineer team to design custom parts for your needs , we also have ready-made standard moulds that can save your cost and time . We offer ODM/OEM service, Production Design and Mould Design base on your requirement . Providing the sample before mass production , ensure all is OK for you . If you have any problems or want to get the quoted price of any plastics or machined components, please feel free to contact us. Our engineers will reply to you as soon as possible.A wide range of injection mold optionsOur products cover auto parts mold, electrical appliances injection mold, medical machinery and so on. We provide products and services to more than 60 countries and regions in the world, including Europe, the United States and Southeast Asia.

Our Factory

Our factory has 100 sets of precision processing equipment, welcome to visit our factory!

One-stop ServiceOEM, ODM, Customization service,Reasonable and competitive price,Design for Manufacturability (DFM) analysis with every quote,Short Delivery Time.

Reliable mold expert 15+ years' experience, Cooperated with many world famous brands for many years, Specialize in large and complex injection mold making, One-stop service from design to production.

Certification

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.

Professional team

Our company is developing in the mode of quality for survival, brand for development and customer's demand, welcome new and old customers to visit our factory for guidance.

Client WitnessOur Exhibition & CCTV Interview

Buying Instructions

Q1. Can samples be produced?A1. YesQ2. What is the accuracy of the products processed by the drawings?A2. Different equipment has different accuracy, generally between 0.05-0.1Q3. What craftsmanship do you have for processing accessories?A3. According to different products, different processes are used, such as machining, extrusion, injection molding, etc.Q4. What are your processing equipment?A4. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine, extruder, moldingmachineQ5. Can you help assembling the product after it is made?A5. It's okayQ6. What certifications or qualifications does your company have?A6. Our company's certificates are: ISO, ROHS, product patent certificates, etc.Q7. Can injection products be surface treated? What are the surface treatments?A7. It is ok. Surface treatment: spray paint, silk screen, electroplating, etc.