Custom Make EPDM Silicone NBR Neoprene Rubber Grommet Dustproof Protective Bushing Sleeve Dust Cover Expansion Bellow

Basic Info

| Material | EPDM |

| Capability | Acid Alkali Resistant Rubber Hose |

| Color | Black |

| Materials | Rubber, Silicone, EPDM, Nitrile, FKM, Neoprene |

| Forming | Rubber Compression/Injection Molded |

| Hardness | 30-90 Shore a |

| Function | Anti-Dust & Water & Oil & Grease & Acids etc |

| Applications | Pump, Vacuum Suction, Medical |

| Working Temperature | -40c~230c |

| Design Type | Tapered, Straight, Metal Rubber Overmolding etc. |

| OEM&ODM | Yes |

| Typical Applications | Expansion Joint, Covers, Sealing etc. |

| Transport Package | PP Bags, Carton Boxes |

| Specification | SGS, ROHS, FDA etc. |

| Trademark | Better |

| Origin | Xiamen, China |

| HS Code | 39241000 |

| Production Capacity | 100, 0000/Month |

Product Description

Custom Make EPDM Silicone NBR Neoprene Rubber Grommet Dustproof Protective Bushing Sleeve Dust Cover Expansion Bellow

Rubber Bellows, known as rubber expension joints, rubber dust boots, which are used as a cover or expansion joint to protect device or machines against dust, water, oil, grease, acids, bleaches, spatter or other environment elements.

Rubber bellows are made by rubber compression molding, rubber injection molding or extrusion tool.

Why choose us to order rubber bellows?

A. Wall thickness tolerance: less than 0.05mm

B. Mini or less bellow flashing

C. Mold maintenance aiming to up and down mold plate with horizontal stripe in exact position

D. Good ejected molding to improving rubber bellows production efficiency

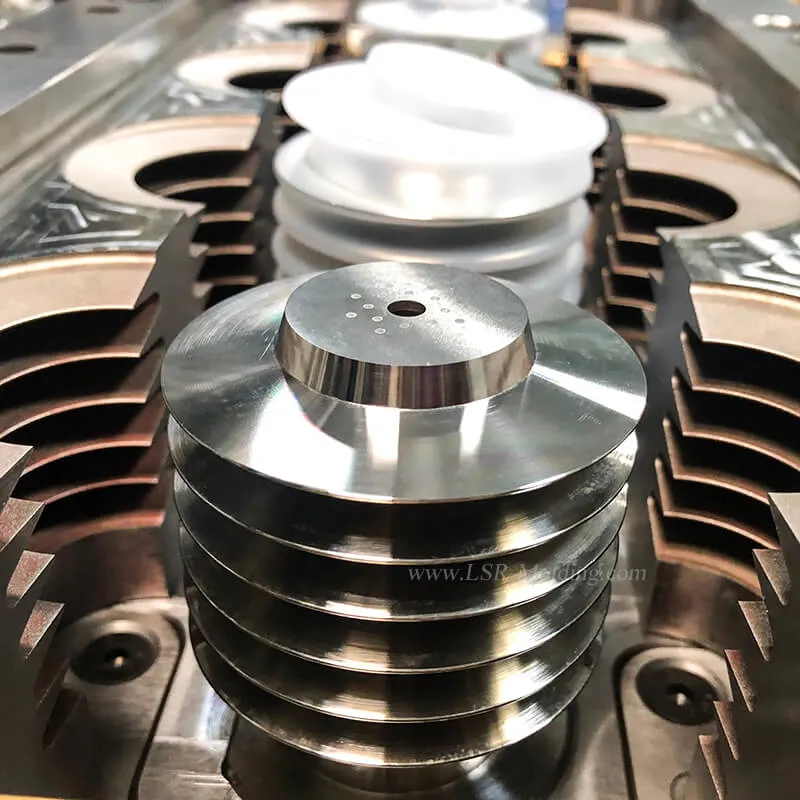

Custom Rubber Bellows Moulds

Liquid Silicone Rubber Bellow

Rubber Bellows Materials

Below are the materials we use to manufacture our rubber bellows, including all physical characteristics. For questions about which material may be right for your application, please contact us.

| Material | Abbreviation | Temperature Range(dry heat) | Aging Weathering Ozone | Oil& Grease Resistance | Water Swell Resistance | Flex-Fatigue | Economy ofMaterial | Material Notes |

| Neoprene | CR | -40F to 250F | Good | Good | Average | Very Good | Good | exposure to refrigerants,can be compounded for FDA applications |

| Nitrile | NBR | -22F to 212F | Poor | Very Good | Good | Good | Very Good | Automotive Applications,Good Oil Proof |

| Ethylence-Propylene | EPDM, EPM | -60F to 300F | Very Good | Poor | Very Good | Good | Very Good | Outside Applications,Good Weather Proof |

| Silicone | VMQ | -75F to 450F | Very Good | Average | Very Good | Very Good | Average | Medical Applications |

| Fluorocarbon | FKM | 5F to 390F | Very Good | Very Good | Good | Average | Poor | Rubber King,Widely Applications |

Rubber Bellows Main Structions and Shapes

Straight Convolution Rubber Bellows

Spiral Convolution Rubber Bellows

Concentric Rubber Bellows

Tapered Rubber Bellows

Metal+Rubber Overmold Bellows

Rubber Bellows with Clamping, Hole & Lock

Square Rubberr Bellows

Rubber Bellows Design Guide

Our Company

Xiamen Better Silicone Rubber Co., LTD, established in the year of 2018, is the production base of Xiamen Better Silicone Import and Export Co., LTD (established in 2015), who is specialized in manufacturing precision silicone rubber parts, LSR (liquid silicone rubber) parts and plastic components. Better Silicone aims at providing the comprehensive one-stop solutions and service throughout the entire production process, from product design analysis, mold design and mold making, sample & prototype, mass production stage and then ready-to-use products (finished product). Our Products can be widely used in Electronic Field, Medical Field, Auto parts & machinery parts field, etc.